CE Marking and CE Labelling

We are fequently asked about CE Marking and what is required to affix the CE Label, how does it work and what do we do.

The process of CE Marking is quite straightforward and involves the simple protocol below.

1. Establish the applicable Article 100A EU Directives

2. Perform a statutory recorded risk and hazard assessment for each machine, product or process

3. Research & Apply the appropriate harmonised standards

4. Test and assess against the requirements of these standards

5. Establish the quality control systems to manufacture the product, machines and processes

6. Create the Technical File for the product

7. Issue when appropriate the Certificate of Compliance

8. Issue when appropriate the Declaration of Conformity?Incorporation and Apply the CE Mark

Generally this applies to ALL CE Marking Directives and should form a guide to what is needed.

Appropriate EU Directive(s) Examples are:-

The Machinery Directive (06/42/EC)

The Low Voltage Directive (72/23/EEC)

The EMC Directive (04/108EC).

The Pressure Equipment Directive (97/23/EC)

The ATEX Directive (94/9/EC)

Here at DSEAR Consultancy we deliver all the services to ensure complete assurance that your product meets the applicable EU Directive.

Please contact us to see how we can help you

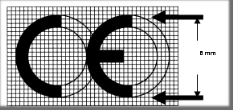

Two concentric circles, not less than 5mm in height.

Never stylise the image, and keep the proportions the same.

It must be clearly visible, and unambiguously identifiable, and satisfy a rub test, if you want to try it out for yourself then as a rule of thumb (sic.).

You need

Iso-Propyl Alcohol

A lint free cloth

Dip the cloth in the alcohol and rub the image for a period of one minute, after this time the CE Mark must remain visible and identifiable